Intumescent Coatings

Intumescent Coating Painters & Decorators Northampton

Intumescent Painters and Decorators in Northampton

Intumescent paint is a type of paint that expands when exposed to high temperatures. This expansion creates a layer of insulation that protects the underlying surface from heat damage. Intumescent paint is often used to protect structural steel in buildings from fire.

How Intumescent Paint Works

Intumescent paint contains a number of chemicals that react to heat. When the paint is exposed to temperatures above 120°C, these chemicals start to expand. This expansion causes the paint to form a thick, foam-like layer that insulates the underlying surface. The insulation layer prevents the heat from reaching the underlying surface, which helps to protect it from damage.

Types of Intumescent Paint

There are two main types of intumescent paint: thin film and thick film. Thin film intumescent paint is the most common type. It is applied in a thin layer and provides a fire resistance rating of 30, 60, 90, or 120 minutes. Thick film intumescent paint is applied in a thicker layer and provides a fire resistance rating of up to 240 minutes.

Application of Intumescent Paint

Intumescent paint can be applied by brush, roller, or spray. It is important to follow the manufacturer’s instructions carefully when applying intumescent paint. The paint must be applied evenly and to the correct thickness.

Benefits of Intumescent Paint

Intumescent paint offers a number of benefits, including:

- It provides fire protection for structural steel.

- It is easy to apply.

- It is relatively inexpensive.

- It can be overpainted with a decorative finish.

Where to Use Intumescent Paint

Intumescent paint is often used in the following areas:

- Structural steel in buildings

- Steel beams and columns

- Steel staircases

- Steel gantries

- Steel tanks

Conclusion

Intumescent paint is a valuable tool for fire protection. It can help to protect structural steel in buildings from fire damage, which can save lives and property. If you are looking for a way to protect your building from fire, intumescent paint is a good option to consider.

Contact Us

If you are interested in intumescent painting services, please contact us today. We would be happy to discuss your needs and provide you with a quote.

We are experts in the application of intumescent coatings and can provide detailed advice on their function and application.

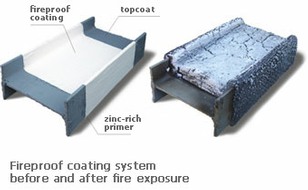

Expanded thin film intumescent coating

Intumescent coatings are paint-like substances that are inert at low-temperature ranges yet supply insulation because of an intricate chemical effect at temperature ranges generally around 200-

Intumescent coatings are generally split into 2 broad types: thin film and thick film. Thin-film products can be solvent-based or water-based and are mostly employed for cellulosic fire situations. Thick film intumescent coatings were initially produced for the off-

Thin-film intumescent coatings

Thin-film intumescent coating products usually have 3 elements, a primer, a basecoat (the component that functions in the flames) along with a sealant layer. The basecoat normally consists of these elements:

- A catalyst that breaks down to generate a mineral acid like phosphoric acid.

- A carbonific-like starch that mixes with the mineral acid produces a carbonaceous char.

- A binder or resin that softens at a set heat level.

- A spumific agent that breaks down along with the melting of the binder, to free significant quantities of non-

flammable gases. These gases consist of co2, ammonia, and water vapour. The creation of these gases will cause the carbonaceous char to expand or foam and enlarge to offer an insulation coating several times the initial layer thickness.

These are primarily utilized in buildings where the fire resistance specifications are 30, 60, and 90 minutes. Nowadays, several systems have been formulated that can deliver Two hours fire resistance. They may be applied either on-

Normally, almost all on-

Both solvent-based and water-based coatings may be used to attain appealing surface finishes. If a creative or custom finish is needed, this ought to be included in the specification. Thin-film intumescents possess the extra benefits that they can conveniently go over intricate shapes and post-

Standard expansion ratios are about 50:1, i.e. a 1mm thick layer can enlarge to around 50mm whenever impacted by fire.

Comprehensive advice on the standards and application of site applied, thin-film intumescent coatings can be obtained from the Association for Specialist Fire Protection

Thick Film

Thick film intumescent coatings are generally epoxy-based and frequently have a significantly higher dry film thickness compared to thin-film options. These types of products are robust and sturdy and were initially produced for use with hydrocarbon fires, in which the test heating regimen is a lot more extreme compared to that employed for the majority of industrial and business purposes. Several suppliers have customised their products for usage in cellulosic fires. These types of customized products are generally utilized in circumstances in which the advantages of intumescent coatings regarding the visual appeal, weight, and thickness are needed but where conditions are too extreme, or servicing too hard, to permit using thin-film products. Typical recent instances have taken place in exterior steel in high-

Expansion ratios for thick film intumescents are a lot less than for thin-film materials, usually around 5:1. Artistic surface finishes are achievable and they can even be delivered by way of preformed casings. Thick film intumescent coatings can also be applied off-

10 Benefits of Intumescent Painting For Commercial and Industrial Premises

- Protect steel from corrosion and rusting, increasing the lifespan of the metal

- Protect other materials such as wood, plastic and rubber from fire damage, prolonging the life of the material

- Intumescent coatings form a char layer when exposed to heat, which acts as an insulating barrier and can prevent fire from spreading

- Can be applied to most surfaces without the need for a primer, making them quick and easy to apply

- Available in a variety of colours, allowing you to match the coating to your décor

- Available in both gloss and matt finishes, giving you the flexibility to choose the finish that best suits your needs

- Non-toxic and environmentally friendly, making them safe for use in homes and workplaces

- Resistant to fading and staining, meaning they will continue to look good for years to come

- Low maintenance and easy to clean, meaning you won’t have to spend hours cleaning them

- Increase the value of your property, making them a wise investment for any home or business owner.

Call us today for a detailed quote.

PROFESSIONAL PAINTERS LTD

©Pro-Painters Northampton

Phone: 0800 044 3604 E-Mail: info@professionalpainters.co.uk